Whether you are a beginner blacksmith looking for a new forging material or an experienced expert smith, wrought iron is an excellent material choice for many blacksmiths. Wrought iron has unique properties that give it a beautiful appearance. You can use it in a variety of pieces, and it makes a great decorative option for any smithing project. Although working with wrought iron is similar to working with cast iron, keep reading to understand the blacksmithing techniques for working with wrought iron and its properties.

What Is Wrought Iron?

Wrought iron is a type of iron alloy that possesses a very low carbon content. It has fibrous slag inclusions that appear when this type of iron is bent or etched, which is why it is popular for decorative pieces and blacksmithing. It doesn’t possess many carbon impurities, making it a tough, malleable, and resistant metal that is popular in blacksmithing and welding.

Different Types of Wrought Iron

There are two main types of wrought iron, known as charcoal iron and puddled iron. When crafting charcoal iron, the goal is to remove as many impurities from the metal as possible. Blacksmiths achieve this through the process of heating it to just below melting point and then working the impurities out using hammering tools on an anvil.

Puddled iron is different from charcoal iron because smiths craft it through the puddling process, which stems from the process that is used to create cast iron. Like charcoal iron, the goal of creating puddled iron is to remove all impurities, though the processes to achieve its purity are different. Blacksmiths use an oxidation process to purify puddled iron. This involves continuously mixing cast iron in the furnace to remove these impurities.

Benefits of Working With Wrought Iron

There are many benefits to working with wrought iron as a blacksmith. Due to its purity, wrought iron is a hard iron alloy though incredibly easy to work with, making it a popular metal for blacksmiths of all skill levels. It is also very ductile and malleable, which allows you to mold it into a variety of shapes. You can often find wrought iron for use in decorative pieces and iron fencing because these shapes are easy to work with and form. You can also easily reheat wrought iron for reforging and editing purposes along the way. If you’re not happy with the first pass, you can reheat wrought iron and strengthen it to try your shape again.

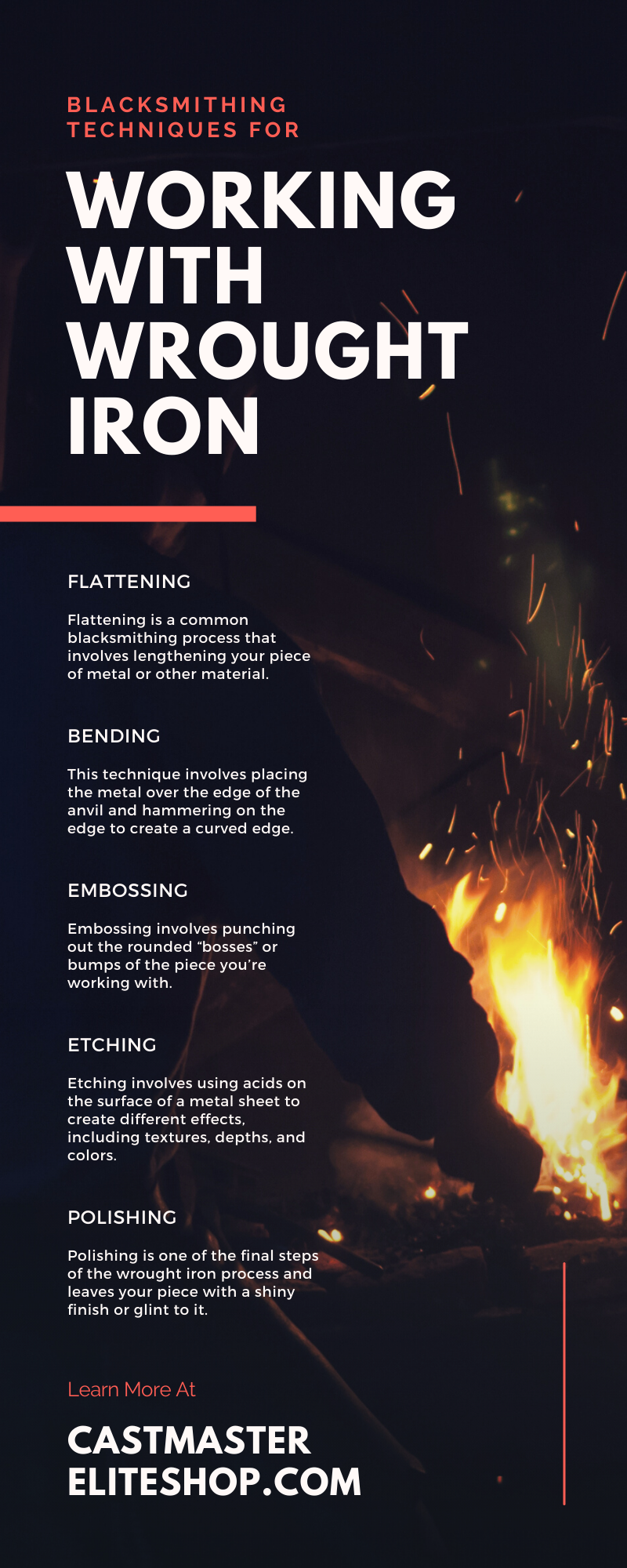

Wrought Iron Forging Techniques

Keep reading to learn the various techniques for working with wrought iron. Although you might already have a grasp of some of these techniques, there are some extra techniques that you might not know or may not have yet practiced due to the decorative nature of wrought iron.

Flattening

Flattening is a common blacksmithing process that involves lengthening your piece of metal or other material. Flattening a material helps give you more material to work with and thins out the piece you’re working with. Striking with the narrow edge of the hammer will be more effective in this case than striking with the flat face. If you happen to bend or twist the piece along the way, you can simply reheat and straighten it back into shape.

Bending

You can perform the metal bending process while the material is warm or cold. This technique involves placing the metal over the edge of the anvil and hammering on the edge to create a curved edge.

Impressing

Impressing involves making impressions on a metal sheet to create hollow, rounded forms or other shapes. Punches or chisels need to be used when working with thicker sheets.

Embossing

Embossing involves punching out the rounded “bosses” or bumps of the piece you’re working with. You may create bosses in a piece of metal with a rounded hammer when the piece of metal is cool.

Engraving

Engraving is a decorative technique that involves cutting flat or sometimes linear lines into the surface of the metal sheet. You’ll need a “graver” or “graving tool” to complete the engraving process. Though, you can use a hammer to perform a technique called “cutting in iron.”

Etching

Etching involves using acids on the surface of a metal sheet to create different effects, including textures, depths, and colors. Sometimes etches in metal are varnished to create an even deeper appearance.

Polishing

Polishing is one of the final steps of the wrought iron process and leaves your piece with a shiny finish or glint to it. Other polishing processes include bronzing or browning, which leave the appearance of an oxidized surface.

Tools for Working With Wrought Iron

When working with wrought iron, you’ll need many of the same tools for working with traditional iron alloys. Some of the basic tools you’ll need include your forge, tongs, vices, an anvil, a quenching bucket, and your desired strength and shaped hammers. Because wrought iron is a great material for beginners, work with the tools that you have to practice. And if you’re in need of blacksmithing tools to add to your repertoire, visit our shop page at Cast Master Elite to find a variety of forging equipment for sale. You can find everything you need, from beginners’ tools and small crucibles to entire forging kits to get you started.

Now that you know the proper blacksmithing techniques for working with wrought iron, you should be more comfortable exploring this new medium. Wrought iron is a great metal to work with for any blacksmith, whether you’re a hobbyist just getting into the craft or an expert who sells their works. If you need to stock up on any tools to get your workshop stocked for this new project, don’t forget to check out our selection of forging equipment here at Cast Master Elite. Among our selection, you can find crucibles and forging equipment that are perfect for working with a variety of materials, including wrought iron and more. You’ll have everything you need to get started working with this new material.